- Simple design

- Regenerative circuit

- High flow and high speed

- Low power dissipation

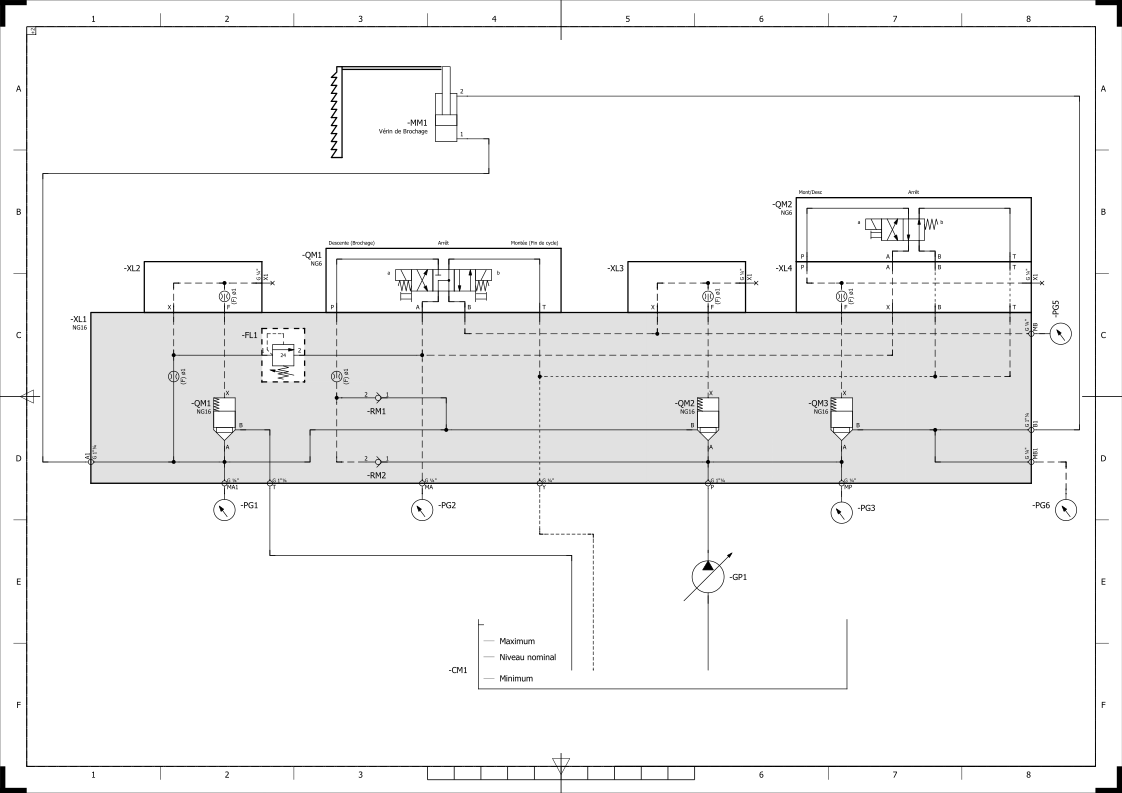

The system is supplied by a variable-displacement pump. When the machine stops, all control valves are in their initial position.

Pump pressure acts simultaneously on port A of the cartridge elements (XL1-QM2 and XL1-QM3). At the same time, the pressure acts on port 2 of the pressure relief valve (XL1-FL1) via the pilot line, keeping it closed. As a result, both cartridge elements are closed in direction A to B. The pressure in the cylinder on the piston side, due to the weight of the broaching carriage, keeps the XL1-QM1 cartridge closed.

For the pinning operation, solenoids -QM1a and -QM2a are energized. Pilot pressure acts on the control section of element XL1-QM2 to keep it closed. The control section of cartridge element XL1-QM3 and orifice 2 of limiter XL1-FL1 are relieved. Fluid is delivered from the pump through XL1-QM3 to supply the rod-side pinning cylinder.

The barrel-side cylinder return flow is returned to the reservoir after being restrained (24bar) by the XL1-FL1 pressure relief valve via the XL1-QM1 cartridge valve.

The broaching carriage is returned to its initial position by energizing solenoids -QM1b and -QM2a. This locks the XL1-FL1 limiter. At the same time, the control section of the XL1-QM2 cartridge element is decompressed.

The pump flow is returned from A to B to feed the cylinder on the barrel side. Cartridge element XL1-QM1 remains closed (previous paragraph): the rod extends, meaning that the broaching carriage and its spindle return to their initial position. The flow on the rod side is returned to the pump line via the XL1-QM3 cartridge valve from B to A, via a regenerative circuit.