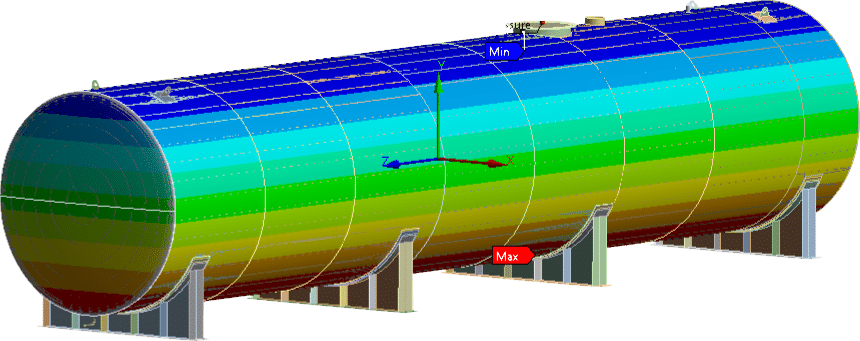

- Construction of a large-capacity water reservoir (50 m3)

- Optimization of tank mass (tare), guaranteeing a reliable, raw-material-saving design

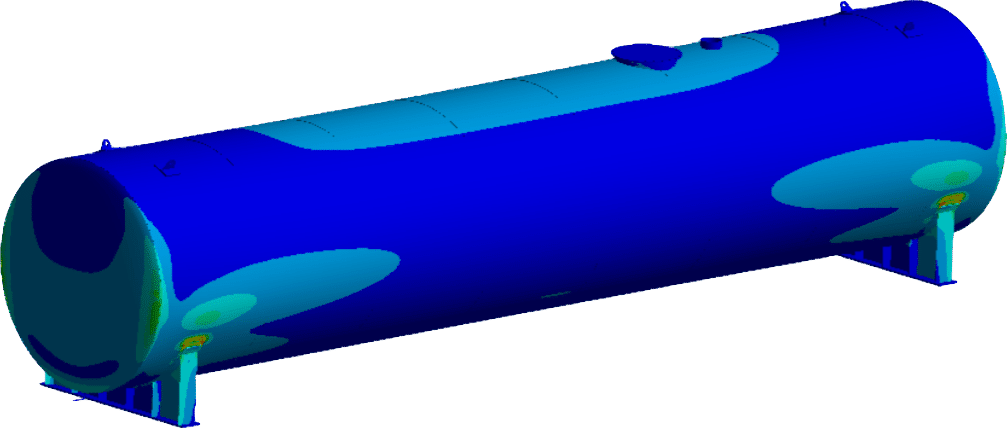

- Validation of lifting zones to ensure safe handling

- Weld sizing

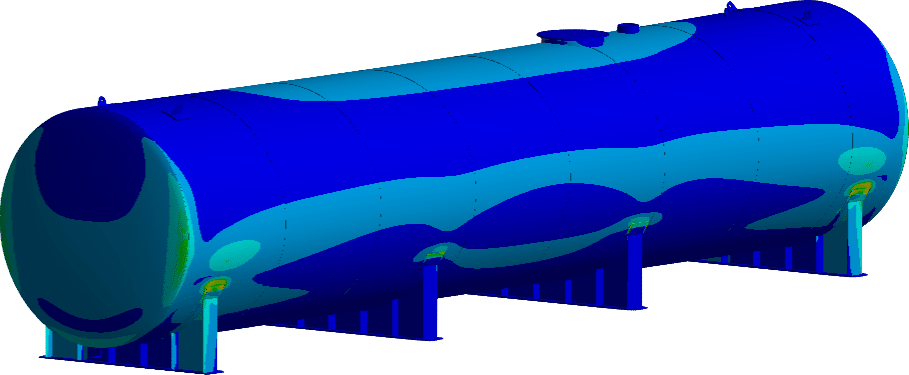

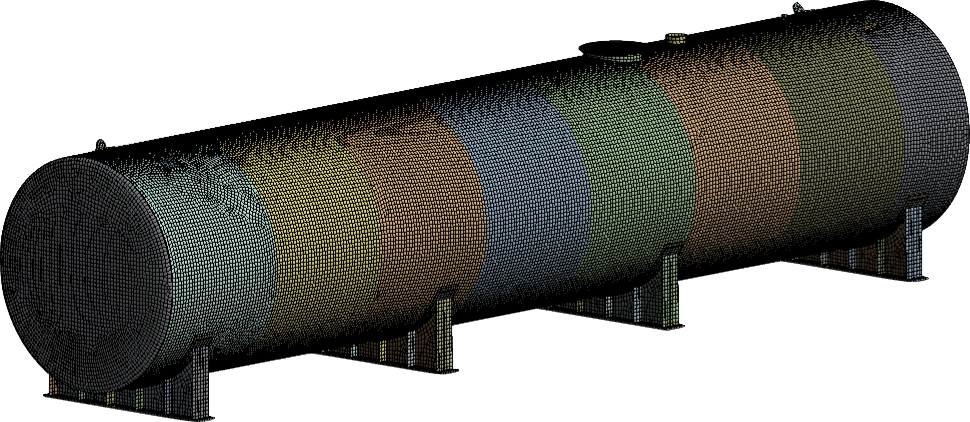

To achieve the objectives set by the customer, a finite element calculation was needed to give us a detailed view of the tank. In order to optimize the plate thickness, we carried out a parametric analysis. This enabled us to propose thinner plates, while maintaining a level of safety above the standard, and thus saving weight.

After analyzing the basic results, we decided to propose the following modifications to the customer:

- Reduced sheet thickness for lighter weight

- Removal of the two central supports

- Validation of weld seams

- Lifting point reinforcement

Simulations showed that it was not necessary to keep the two central supports. They were simply removed. The fixing points for lifting and positioning the tank were too weak: we validated our model and signed a calculation certificate. The level of resistance is guaranteed throughout the tank, and costs have been optimized.